Address: 393-J Tomkins Ct. Gilroy, CA 95020

Phone: (408) 848-2851

Fax: (408) 848-5763

| |

| Home |

| Products |

| Services |

| Contact Us |

| Signatone Division |

| Lucas Labs Florizel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Testing Systems for Mass Flow Controllers

The MFC standard tester is intended to be used with benign test gases (nitrogen, argon etc.) and will yield the actual flow for the gas being tested. An all dry pumping stack is provided for such applications, with or without a front end hybrid turbo/molecular drag pump, according to the base pressure required. This facility eliminates oil from the exhaust of florizel and provides greater latitude for the testing environment. An oil pumped system, at reduced cost, is also available. "Real" process gases, including corrosive gases, can b e tested provided that an optional corrosive pumping stack is substituted on the MFC Tester, and that the user provides appropriate exhaust system and scrubber facilities where required. Florizel- MFC Offline Tester Florizel uses the Rate of Rise in off line testing of Mass Flow Controllers. Florizel reports linearity, off set, gain of MFC performance. At each flow rate, Florizel will report time to control, mean flow rate, maximum flow, and flow deviation. Analog and Device Net compatible MFCs may be tested.

Florizel uses the rate-of-pressure-rise technique to measure the dynamic performance of mass flow controllers under conditions similar to those used in actual processing (i.e. into a vacuum chamber at low pressure). This is in contrast to the standard industry technique, in which MFCs are checked close to atmospheric pressure. As well as the conditions not representing those under which the MFCs will actually be used, there is the further disadvantage that at such high pressures, real gases no longer behave sensibly as ideal gases, necessitating a need for correction factors (not universally applied) and complicating the analysis. A further disadvantage is that the standard technique does not measure the real time behavior of the MFC, so such tests do not quantify short term flow fluctuations or the important switch-on characteristic of the MFC. By contrast, Florizel measures real-time behavior with 25 msec resolution.

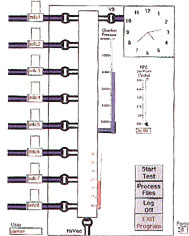

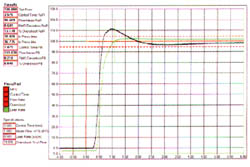

The Lucas Florizel separately quantifies the leak rate to that the true flow rate from the MFC can be evaluated. This evaluation relies on a precise knowledge of the test chamber volume as well as the chamber absolute temperature, which is continuously measured by the Florizel. Florizel looks very similar to the popular Lucas Vacuum Diagnostics System (VDS) except that a sample chamber with multiple connecting ports for the mass flow controllers is mounted on top. Florizel Automation All of this testing is carried out fully automatically, after appropriate set-up. Tests are defined (e.g. test set points, test duration, no. of repetitions, etc.) at the engineer level and stored in the computer's data base for retrieval by the operator during MFC installation. This ensures that the test is carried out objectively and is not subject to operation whims. Similarly, the pass/fail control bands are defined by the engineer and again saved in a configuration file. Again, the analysis is made objectively by the computer against these standards. Up to 8 MFCs at a time can be mounted onto the tester (in either horizontal or, optionally, vertical orientations) and tested sequentially in one test cycle,. testing sequentially in one test cycle. Hence, after physical installation of the MFCs and choice of test & analysis configuration, testing is an unattended one-button operation. Analysis All analysis is carried out out rapidly and automatically, without operator intervention, on the testers WindowsTM environment operating system. Data and configuration information is stored in a Microsoft AccessTM database, making it easily available for additional analysis. The measured data of pressure against time during the MFC test are analyzed to yield a quasi-real time flow rate vs. time, corrected for chamber leaks and chamber temperature, etc. Assessments are made of:

The actual results are compared with user-defined control bands and alarm bands, which are defined with respect The control point is defined as that point where the flow rate first appears within the control bands and stays there, except for short-term fluctuations. Having defined the control point, the mean flow is an indication of the average flow from the control point to the termination of the test. Similarly the flow stability is a measure of the RMS fluctuations of the flow about that mean flow. The maximum flow overshoot is measured and checked against yet another user-defined limit. All points are checked and flagged if, after reaching control, any excursion is outside the user-defined alarm band.

Florizel Specifications The Lucas Florizel uses the rate of pressure rise technique to test the mass flow controllers. The rate-of-rise technique, more fully described as a measurement technique using the rate of pressure rise in a constant volume to determine flow, is a primary measurement technique and an American Vacuum Society standard. It depends on pressure, volume, temperature and time, all of which can be traced to NIST calibration references. This method is described as AVS standard 2.2- 1968 in Journal of Vacuum Science and Technology 5,219 (1968).

The MFC tester is built on the same frame as the VDS and is 22" wide x 36" high, and approximately 300 pounds. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||